Slaughterhouse hook washing

Product

Information

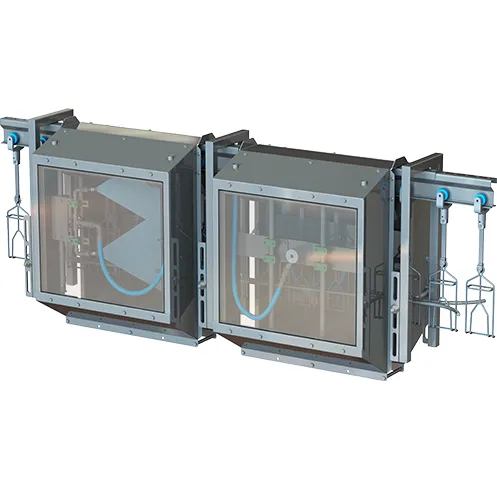

Cleaning of slaughterhouse chains and hooks by application of foam detergent and medium pressure washing, ensuring optimal hygiene. The centralised and automated installation saves water (15 L/min detergent and 35 L/min washing at 40 bar), energy and labour. The detergent and hook washing chambers are installed on the animal conveyor lines in the food processing unit (slaughterhouse). A box is equipped with: - a set of nozzles diffusing the foaming detergent; - nozzles attached to a rotating arm and supplied by the factory's pressurised water network, or by a dedicated plant. The tanks are supplied with pressurised water and detergent by a medium pressure unit and distribution satellites. A PLC automatically controls the cleaning phases of the hooks according to a protocol defined by the quality department.

Sectors

EHSQ

Application markets

Meat / Deli / Poultry

Regions

All