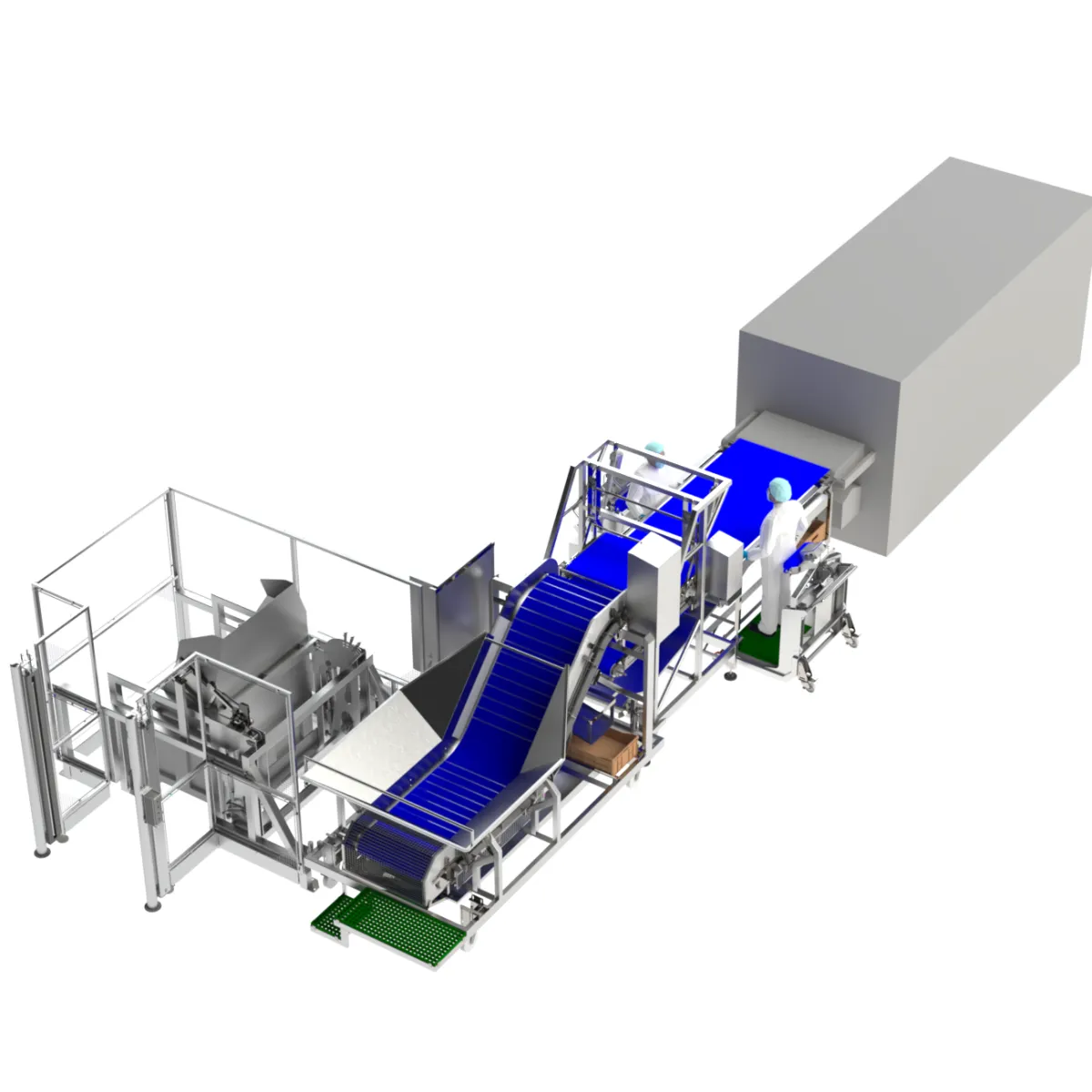

Oven loading

Product

Information

Our equipment enables you to feed your ovens automatically. Depending on your needs and processes, we adapt our solutions and offer several different layouts.

Acemia offers various furnace loading solutions:

Cadenceur: Integrated under the discharge of the elevator conveyor, the cadenceur conveyor optimizes the deposit of products on the conveyor upstream of the oven entrance. The slats on the cadence conveyor belt regulate product distribution, according to their height and spacing. The cadenceur offers the possibility of processing a wide variety of products by changing the belt used. Each recipe requires a specific belt configuration. Thanks to a system that can be dismantled and reassembled without the need for tools, recipe changes can be made quickly and cleaning is optimized.

Flow limiter: The product is discharged onto a conveyor equipped with a second elevated conveyor with adjustable height. The latter acts on the product as it returns from the belt, thus limiting the height of the product flow discharged onto the control conveyor. The automatic adjustment of the conveyor height, performed by electric cylinders according to the recipe selected, guarantees precise adaptation. The flow-limiting conveyor is specially designed for boneless products, ensuring optimum control of product height and promoting uniform cooking.

Manual distribution: A control operation is sometimes necessary at the conveyor to ensure that products are correctly distributed before cooking. Acemia offers ergonomic workstations to help your operators distribute products before they enter the oven, while reducing the risk of RSI.

Mechanical distribution: Equipped with feet that oscillate continuously from left to right and right to left, the mechanical distributor automates and ensures even distribution of your products upstream of your oven.

Our lines can load up to 1.5 tons of poultry per hour at the oven infeed.

Brand

Acemia